Producing wet wipes for babies involves a specialized production line and the use of specific raw materials tailored for gentle use on delicate infant skin.

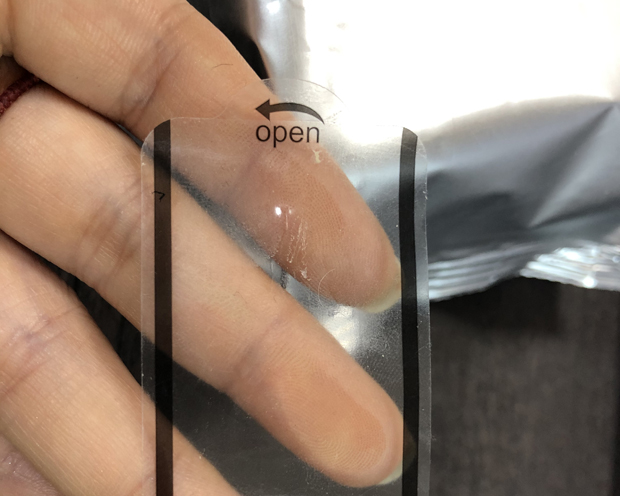

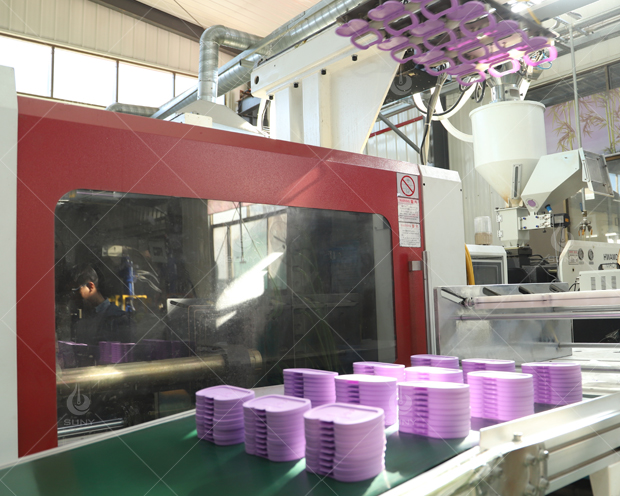

The production line for baby wet wipes is designed to ensure hygiene, safety, and quality throughout the manufacturing process. It typically includes stages such as material preparation, wetting, folding, cutting, packaging, and sealing. Each step is crucial to guarantee that the final product meets the highest standards required for baby care items.

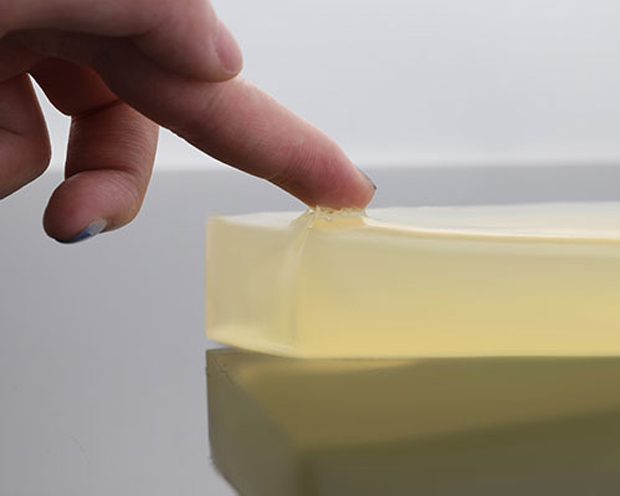

Raw materials used in baby wet wipes production are carefully selected to be soft, gentle, and non-irritating to a baby’s sensitive skin. These materials often include non-woven fabric, purified water, moisturizing agents, mild cleansing agents, and preservatives. The non-woven fabric serves as the base material for the wipe and is chosen for its softness and absorbency. Purified water is the primary ingredient that provides moisture to the wipes without causing skin irritation.

Moisturizing agents such as aloe vera or chamomile extract are added to help hydrate and soothe the skin, while mild cleansing agents gently clean the baby’s skin without causing dryness or irritation. Preservatives are included to prevent bacterial growth and ensure the wipes remain safe for use throughout their shelf life.

In the production line, these raw materials are carefully combined and processed to create high-quality baby wet wipes that are safe, gentle, and effective for everyday use. Stringent quality control measures are implemented at each stage of production to guarantee that the wipes meet all safety and regulatory standards for baby care products.

Overall, the production line for baby wet wipes and the selection of raw materials are crucial aspects of ensuring the production of safe and gentle products for infants. By using the right production processes and high-quality raw materials, manufacturers can create baby wet wipes that provide comfort and cleanliness while prioritizing the health and well-being of babies.