Wet Wipe Production: Raw Material Composition and Application Analysis

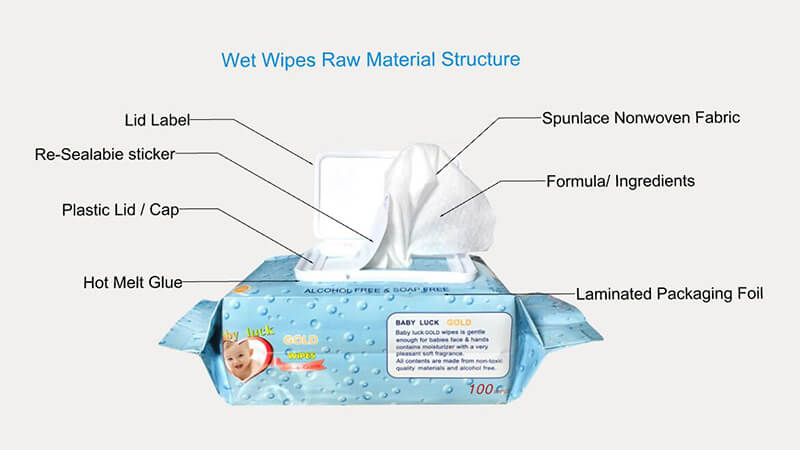

Non-woven fabric is the main raw material for wet wipes, directly determining the product’s feel, strength, and liquid absorption performance. Common materials include spunlace non-woven fabric, thermal-bonded non-woven fabric, and spunbond non-woven fabric. Spunlace non-woven fabric is widely used in baby wipes and personal care products due to its softness, skin-friendliness, and good toughness. Depending on the application, viscose fibers, polyester fibers, or a mixture of both can be chosen to balance cost, environmental friendliness, and user experience. High-quality base materials not only improve liquid retention but also prevent issues such as linting and tearing during use.

Wet Wipe Production: Raw Material Composition and Application Analysis

The liquid in wet wipes is usually based on purified water, with different functional ingredients added depending on the application. Ordinary cleaning wipes mainly contain moisturizers and mild surfactants; baby wipes emphasize being alcohol-free and non-irritating, and include skin-care ingredients such as aloe vera and glycerin; disinfectant wipes contain an appropriate amount of alcohol or antibacterial agents to achieve sterilization. A high-quality formula must not only ensure cleaning ability but also control irritation and stability, ensuring that it does not deteriorate during long-term storage while maintaining appropriate moisture levels.

The packaging material for wet wipes is equally important. Common forms include composite film soft packaging, tub packaging, and single-piece individual packaging. Composite films usually use a multi-layer structure of PET, PE, etc., which has good sealing and anti-volatilization properties, effectively locking in moisture and extending the product’s shelf life. For wet wipes that are opened and closed repeatedly, a PP plastic lid or sticker seal is also provided to improve sealing and ease of use. High-quality packaging not only protects product quality but also enhances the overall user experience and brand image.

In summary, the quality of wet wipes is not determined by a single material, but rather by the combined effect of the base material, liquid formula, and packaging. Rational selection and optimization of raw material structure can not only improve product performance but also provide a competitive advantage in cost control and market competition.