The manufacture of wipes requires a variety of raw materials. These materials can be categorized into substrates (the base material of the wipes themselves), liquid solutions (which give the wipes their moisture and cleaning or sanitizing properties), and other components such as packaging. Below is a detailed breakdown of the raw materials required:

Raw material composition of wet wipes

Substrate (basic material)

The base material is the fabric used for wipes. It must be durable, soft, and absorbent. Common materials include:

Nonwoven: This is the most common substrate and can be made from the following materials

Polyester: Provides strength and durability.

Polypropylene: Often used due to its cost-effectiveness and strength.

Viscose/Rayon: Adds softness and absorbency.

Cotton: Provides excellent absorbency and softness, but is more expensive.

Blends: A combination of polyester, polypropylene, and viscose with balanced properties.

Liquid solutions

Liquid solutions give wipes their moisture and active properties. The composition depends on the intended use of the wipes (e.g. baby wipes, disinfectant wipes, cosmetic wipes). Common ingredients include

Water: The main ingredient, usually purified or deionized water.

Surfactants: Used for cleansing purposes; for example, sodium lauryl sulfate or Cocamidopropyl betaine.

Emollients: Used to moisturize the skin and prevent dryness; examples include glycerin or aloe vera.

Preservatives: Prevent microbial growth in solution; examples include phenoxyethanol, parabens, or benzoic acid.

Fragrance: Used to add a pleasant scent; can be synthetic or natural.

pH Adjusters: Ensure the solution is skin-friendly; examples include citric acid or sodium hydroxide.

Antimicrobial/Preservative: Used to sanitize wipes; e.g. alcohol (ethanol or isopropanol), benzalkonium chloride, or chlorhexidine.

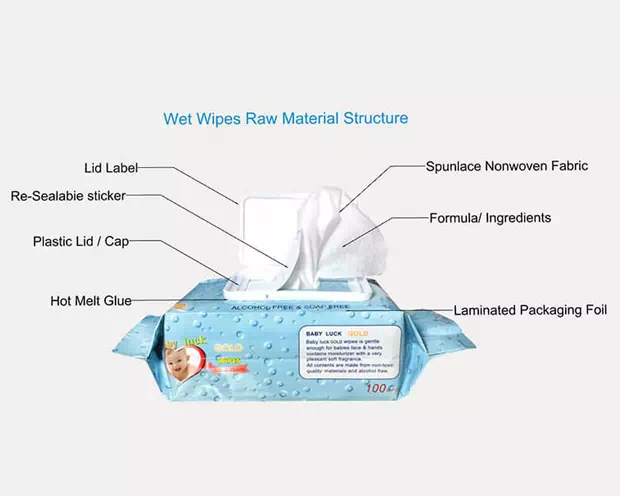

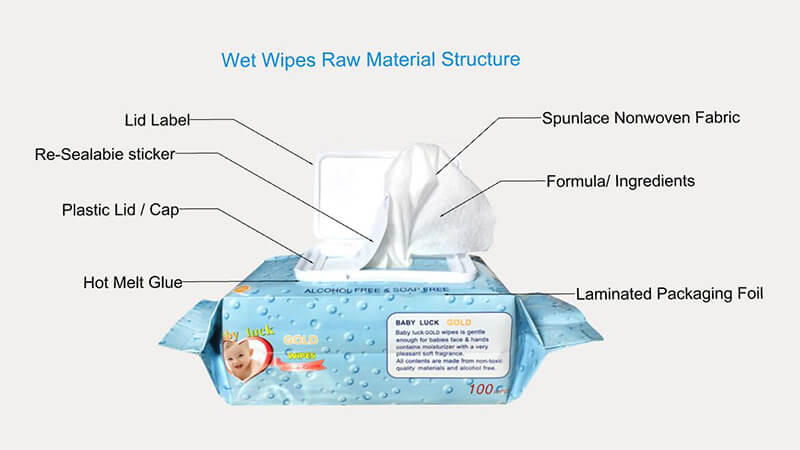

Packaging material:

Plastic film: for individual sachets or flow packs.

Plastic jars: for bulk packaging.

Lids and dispensers: for easy resealing and dispensing of wipes.

Labels and Printing Inks: For branding and information.

Together, these ingredients make wipes effective, safe, and convenient for a variety of uses.