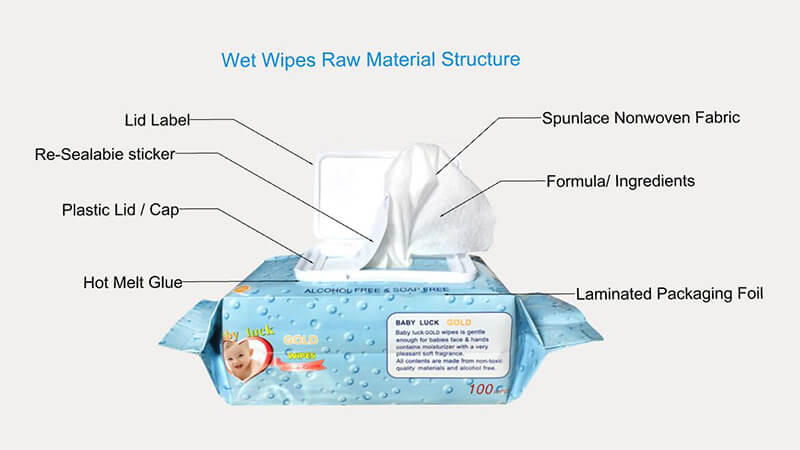

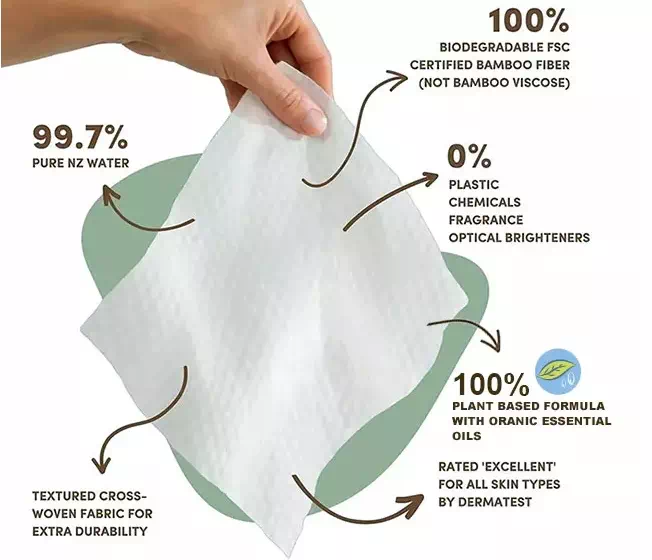

The quality and experience of wipes is closely related to the choice of their raw materials. The base material for wipes is usually a nonwoven, and common materials include polypropylene (PP), polyester (PET) and wood pulp fiber. Polypropylene is widely used for general wipes due to its good moisture retention and strength, while polyester is used for wipes that require greater durability. Wood pulp fiber, on the other hand, is more commonly used in eco-friendly wipes because of its better biodegradability. Choosing the right nonwovens not only improves the strength of the wipes, but also increases the comfort when using them.

In addition to the nonwoven fabric, the wetting agents and cleaning ingredients of the wipes also play a vital role. Moisturizers, such as water, glycerin, and plant extracts (e.g., aloe vera extract), keep wipes feeling moist while providing additional moisturization. Among the cleansing ingredients, surfactants help remove oils and dirt from the skin’s surface, while alcohol is commonly used in disinfectant wipes to provide antiseptic action. Wipes for different purposes will vary in their formulations, for example, baby wipes generally avoid the use of more irritating cleansing ingredients.

In addition, for some skin care wipes and baby wipes, skin care ingredients are particularly important. Common ingredients such as vitamin E, aloe vera and shea butter soothe and nourish the skin, reducing dryness or irritation. Fragrances and preservatives are also common ingredients in wipes. Fragrances add a fresh scent to the wipes to enhance the experience, while preservatives ensure that the wipes are not contaminated during storage, extending their shelf life. It is important to note that wipes for sensitive skin are often chosen to be fragrance-free or use natural fragrances to minimize the risk of allergies.

The formulation of wipes’ raw materials directly affects the functionality and safety of the product. Understanding these key ingredients and their roles will help consumers choose the right wipes for their needs, as well as help manufacturers optimize the quality of their products to meet the needs of different consumers.